Quality

At Cord-Sets Inc., we strive to create a culture of quality focused continuous improvement. We believe that in order to best serve our customers, we must continually work to achieve operational excellence, with the end goal of becoming the best cord manufacturer in the world. We are driven to excel in manufacturing performance, while seeking, refining, and deploying the best quality strategies and tools in the industry. We believe that continuous improvement is a journey, not a destination, and we work tirelessly to develop and implement processes which promote that belief.

Products produced by Cord-Sets conform to RoHS, UL, and CSA requirements, and are regularly certified and registered as such. We employ best practices from USCAR21, IPC, and various industries in order to ensure our products exceed our customer’s expectations.

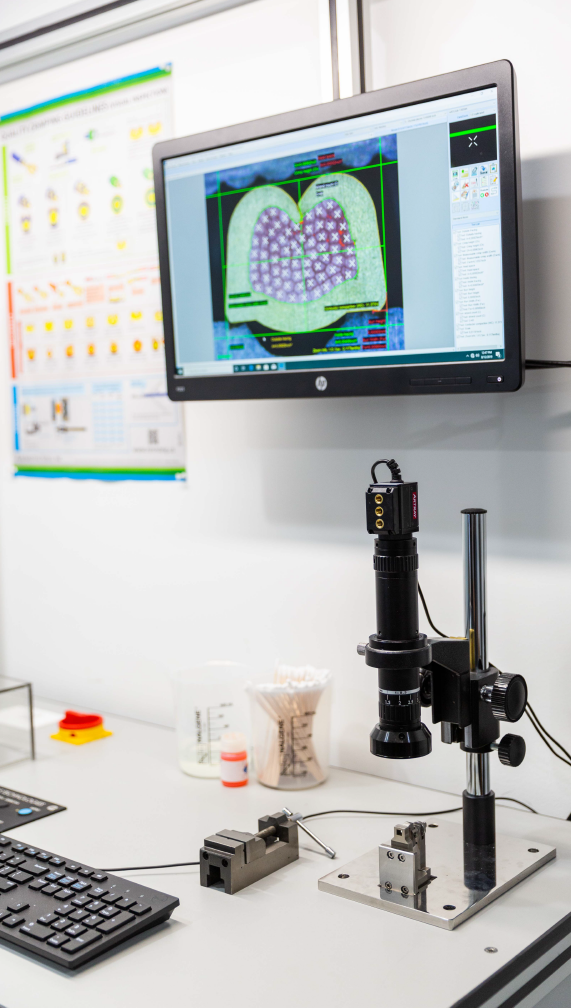

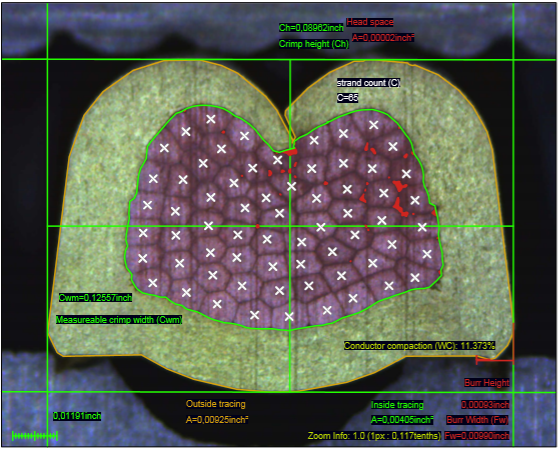

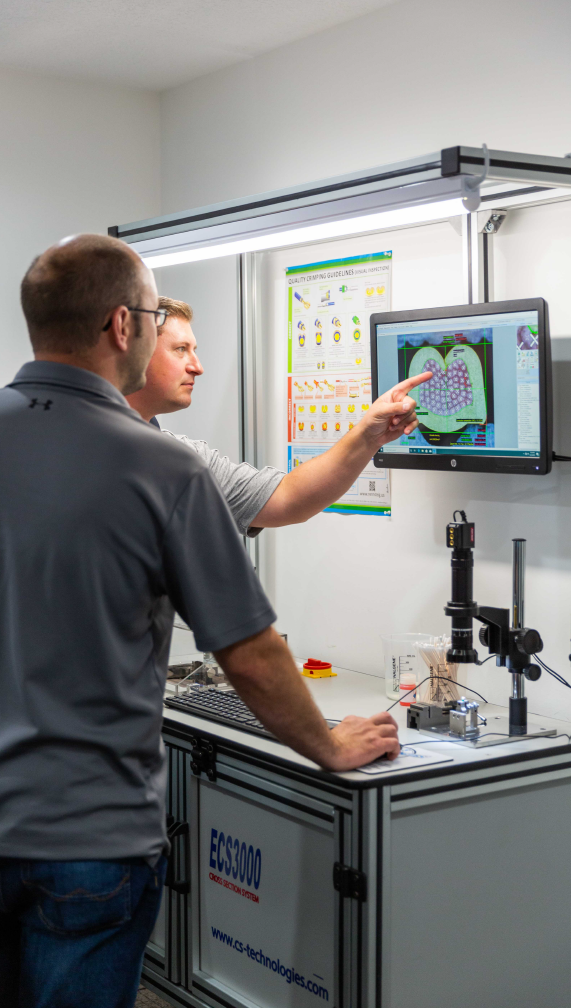

Through the use of our state-of-the-art crimp cross sectioning equipment, we are able to help our customers optimize their product designs, which reduces their risk, and ensures that the products we provide perform optimally for years to come. Our ability to cross section terminals means that we are able to provide a level of quality which is unparalleled in the market.

Cord-Sets Inc. electrically tests every cord produced in order to ensure that no part leaves our facility with poor continuity, dielectric strength, or polarity. We are also able to complete cold resistance tests at our customer’s request. Our customers can rest assured that every cord purchased by Cord-Sets Inc. will perform optimally. For more information on our electrical testing, please CLICK HERE.

At Cord-sets, we strive to foster a safe working environment for all employees through the use of 6S methodology, and believe that a safe and organized working environment positively affects productivity and quality.

We believe that a clean and organized workplace makes it easier to recognize and control potential hazards, and we empower employees to speak up about potential risks and suggestions for improvement. Achieving 100% safety and quality isn’t an easy task, but by incorporating safety into our 5S methodology, we strive to create a cleaner and safer work environment, resulting in unparalleled quality.